71 3 277 284 2006 udc 666 3 127 539 24 jscs 3422 original scientific paper factors affecting the microstructure of porous ceramics du an tripkovi a vesna radojevi b and radoslav aleksi b aictm institute of electrochemistry university of belgrade njego eva 12 p.

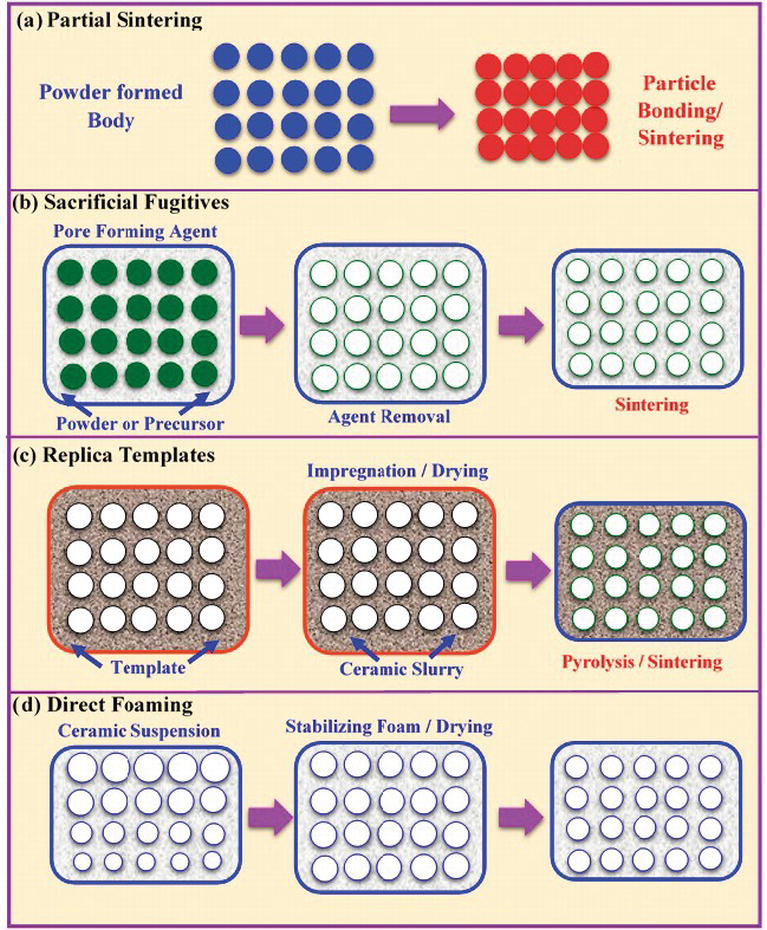

Factors affecting porosity of ceramics.

Factors affecting the porosity and mechanical properties of porous ceramic composite materials.

Ceramics porosity also decrease the cross sectional area over which a load in applied.

Factors affecting the microstructure of porous ceramics pdf j.

Microstructure in dense ceramics materials no large pores the flaw is.

Properties affecting thermal stress resistance of ceramics are reviewed and testing methods are considered.

The porosity and impurities in the ceramic material can be fully eliminated and the grain size of the ceramic material can be properly controlled to make the product close to the theoretical density through the use of high purity ultra fine raw materials with as few additives as possible and strict process control when preparing ceramics thus transparent ceramics were prepared.

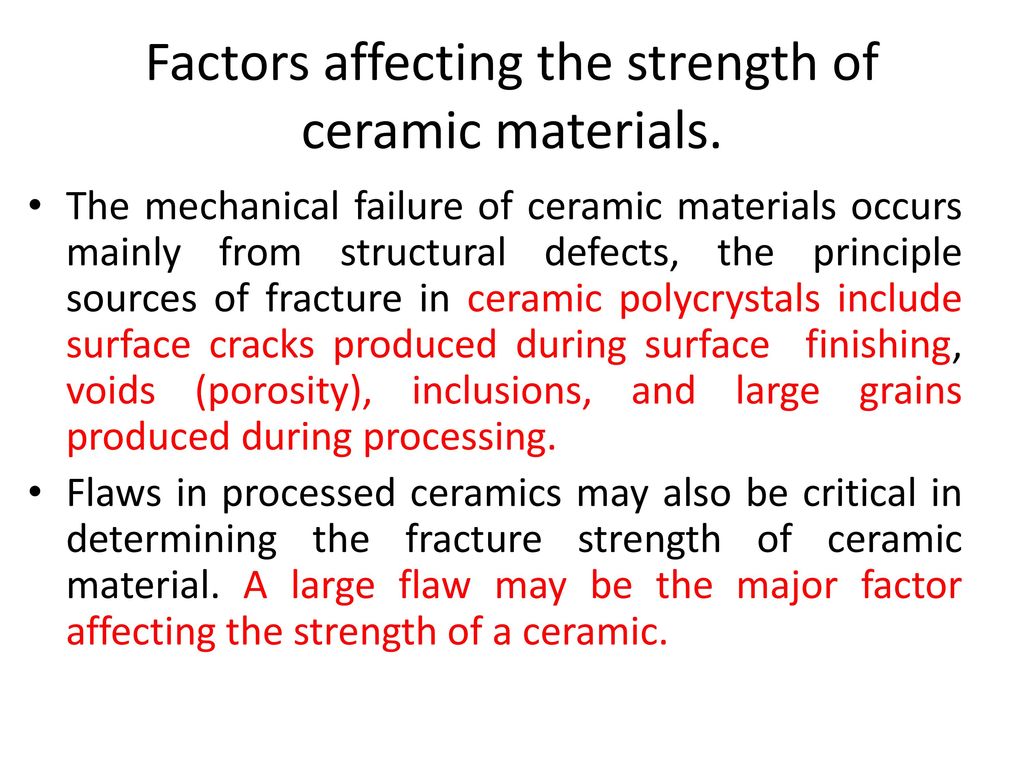

Factors affecting strength of ceramics strength of ceramics is thus determined by many factors.

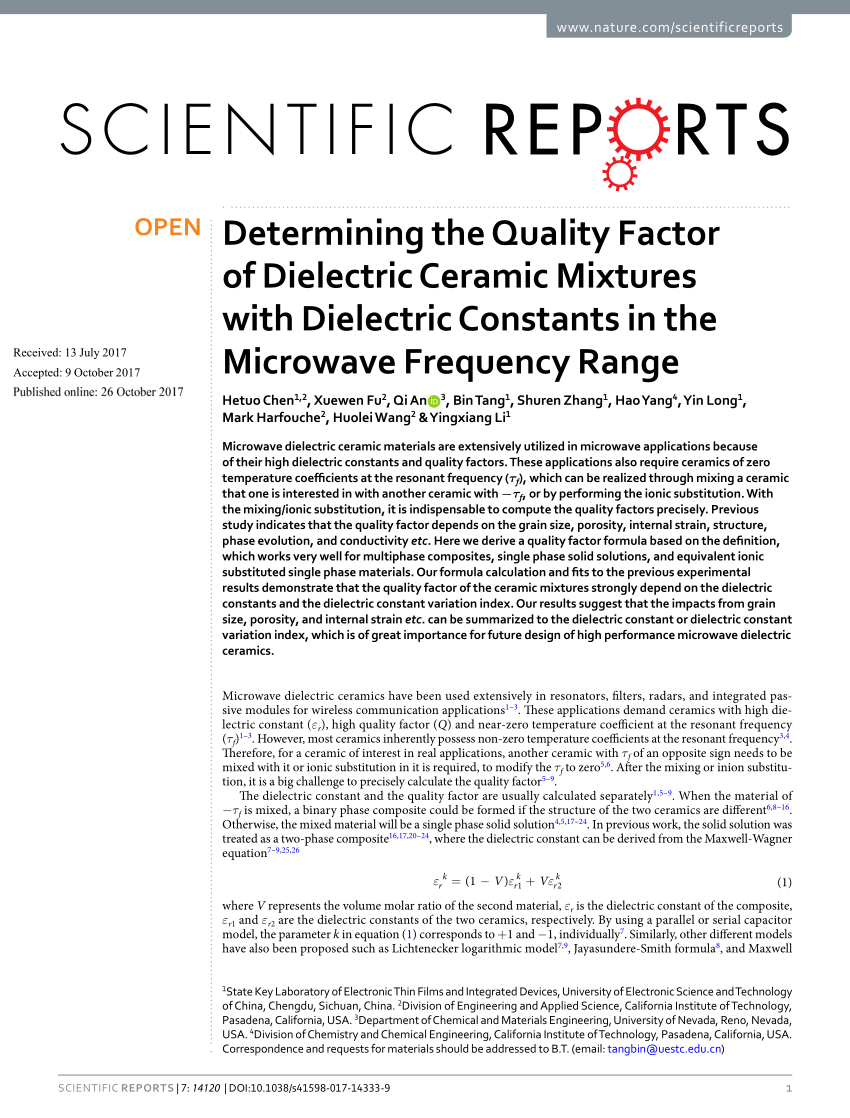

The international journal of applied ceramic technology publishes cutting edge applied research and development work focused on commercialization of engineered ceramics products and processes.

71 3 277 284 2006 udc 666 3 127 539 24 jscs 3422 original scientific paper.

In this study the effects of the major factors on compaction and densification behavior are investigated for ti c n based cermet powders.

Porosity has a very important impact on the performance of ceramics.

It is equivalent to the existence of a defect which can cause stress concentration accelerate crack growth reduce the bonding strength between grains and seriously affect the mechanical properties of ceramics under the action of friction force the pores may connect with each other to form a crack source accelerating the.

Maksarov et al 2014.

Ceramics that include important factors affecting the porosity and the mechanical properties of porous ceramic composite materials.

Lower the stress a material can support.

The sources and calculation of thermal stresses are considered together with the factors involved in thermal stress resistance factors.

It is known that the less is the porosity of a tool material the better are the cutting property and performance of a tool manufactured with the help of powder metallurgy margules 1980.